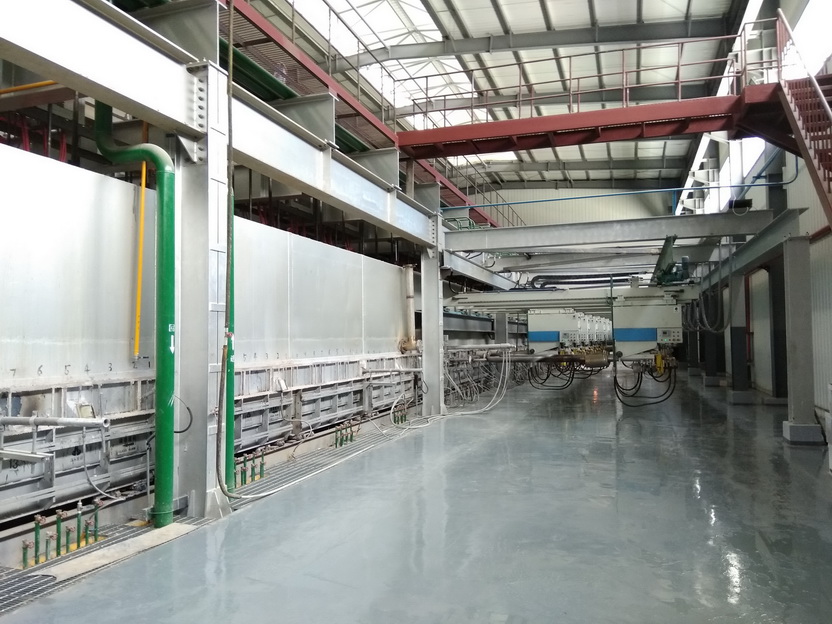

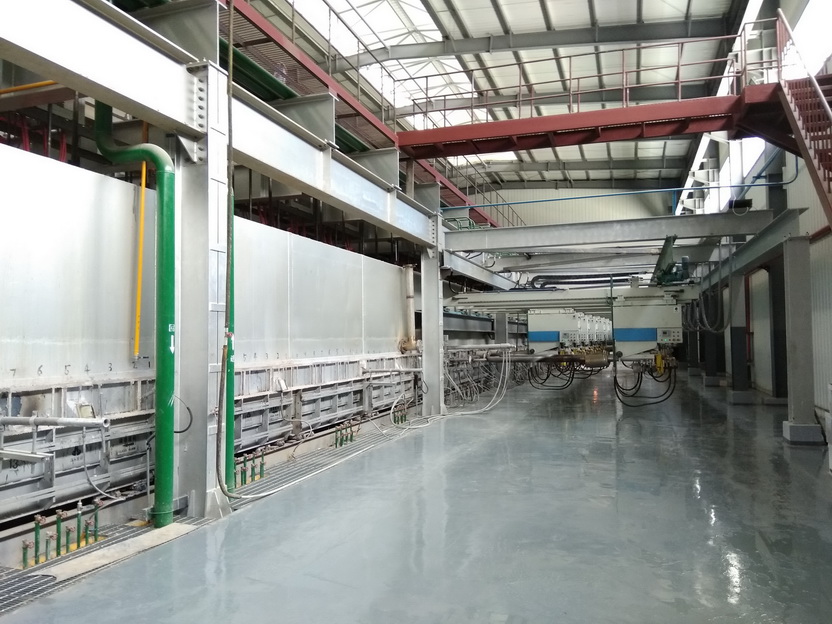

Yunnan DianKai Energy-saving Technology Co., Ltd. 600t/d float glass production line engineering management general contracting

Yunnan DianKai Energy-saving Technology Co., Ltd. is located in the Haiko Industrial Park, Xishan District, Kunming City, Yunnan Province, covering a total area of approximately 421.8 acres. This project is the first phase of a high-grade, high-quality float glass production line with a capacity of 600 tons per day.

The project began equipment installation and construction on October 20, 2016, and was successfully put into production on June 4, 2017.

Pulling capacity: 600t/d, glass slab

rough width 3200mm to 4080mm, thickness 1.8 to 15mm. RUIXIN's main

responsibilities include:

a) Optimizing the original design

according to international company requirements, redesigning the structure of

key parts such as raw materials, melting furnace, and tin bath.

b) Formulating material and equipment

procurement requirements, assisting the buyer in completing the bidding work

for production line materials and equipment.

c) Responsible for the installation of

production line materials and equipment.

d) Providing technical services for

equipment installation: Formulating detailed construction plans according to

the overall progress requirements of the project, guiding and supervising the

construction quality, strictly following construction technical specifications,

and being responsible for the construction quality.

e) Responsible for the temperature rise

and baking of the melting furnace and tin bath.

f) RUIXIN technical personnel lead

production operations, training technical and operational personnel (6 months).

g) Providing a complete set of

technical documents, including equipment material procurement standards,

construction specifications, production operation software, etc.

h) Responsible for one year of production

technical guidance.

The project started

bidding and ordering in April 2016, started equipment installation in November

2016, and officially started production in June 2017. It has completed the

production of glass with a thickness of 1.8mm to 15mm, with excellent quality

in terms of glass slab thickness difference and zebra angle, and the product

meets the requirements for mirror-making and automotive glass.