Supply of complete set of equipment and Technical Service

Our company has successively participated in the design, equipment manufacturing, installation, and trial production technical services for nearly a hundred types of glass production lines both domestically and internationally, accumulating rich experience in engineering design, equipment manufacturing, construction technical services, and glass production practice. Since its establishment, the company has undertaken the design, equipment manufacturing, and production tasks of multiple float and grid-type glass production lines, and has successively developed specialized equipment such as new energy-saving annealing furnaces for float lines, new transitional roller tables, and new edge pulling machines, possessing a suite of proprietary technologies and equipment for thickening and thinning in float glass production.

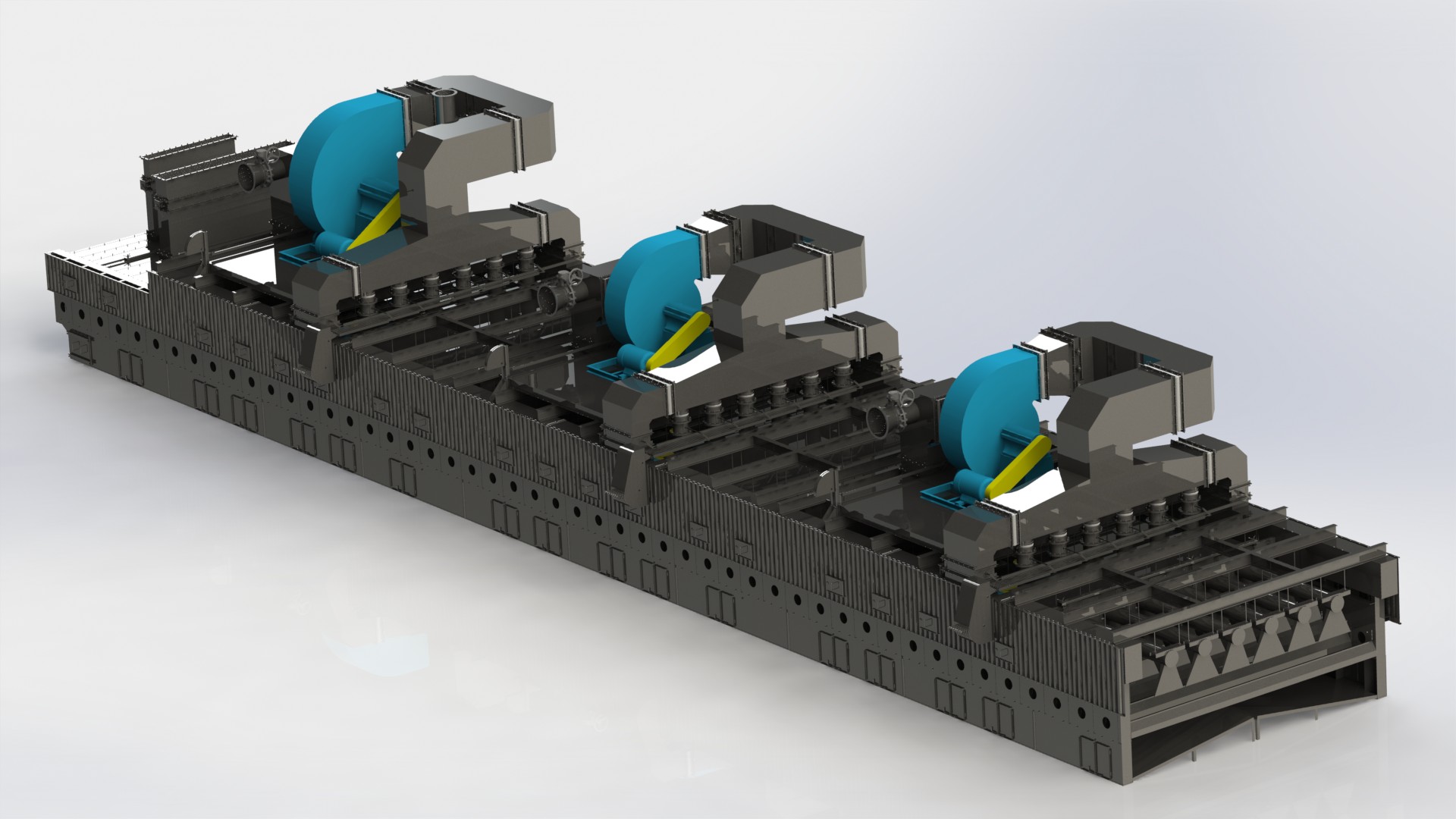

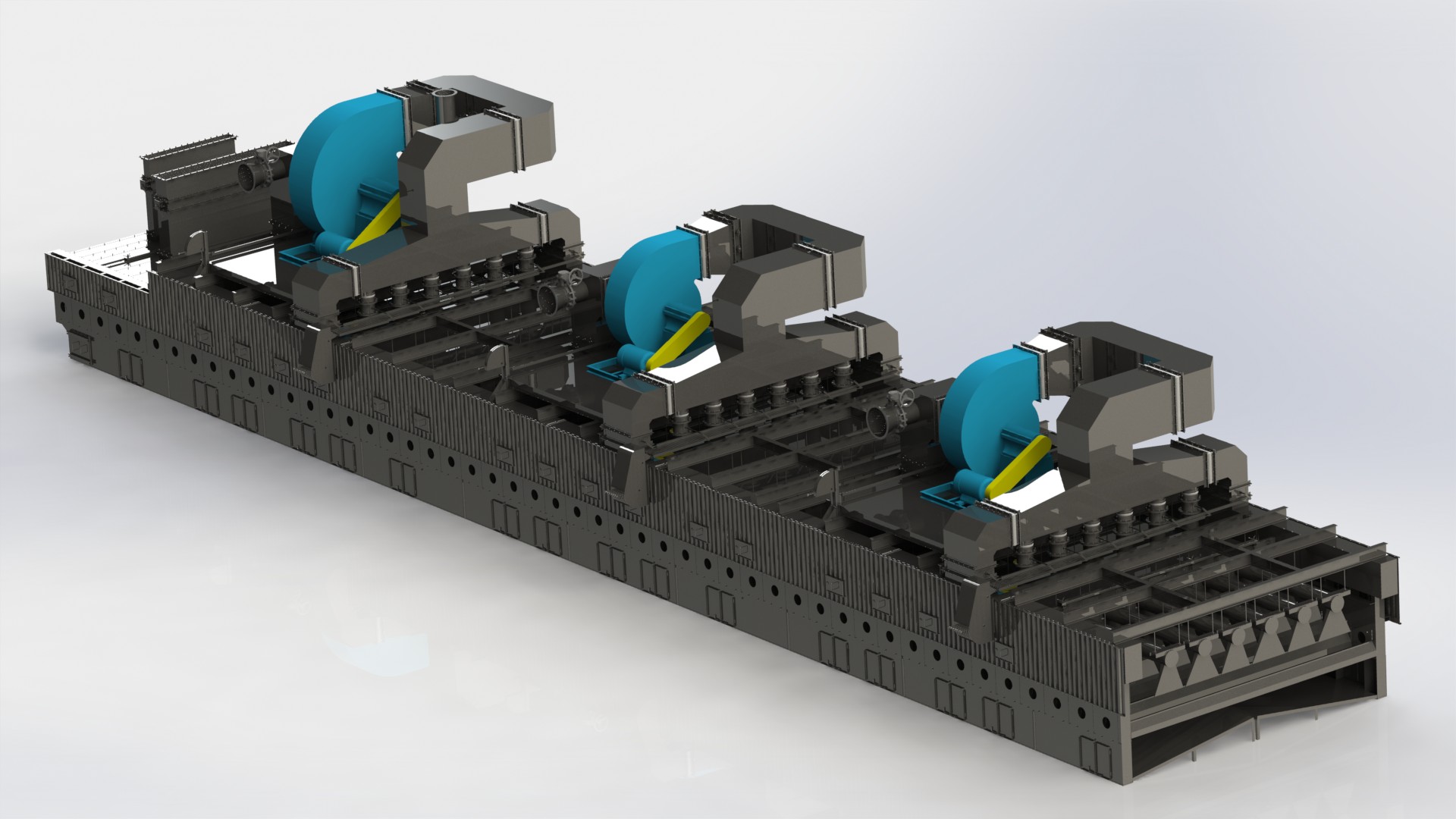

1. Glass Production Line Annealing Furnace

Based on the process technology of RUIXIN's annealing furnace, the glass slab is cooled in a controllable manner. This annealing furnace has the following features:

1.1 The manufacturing and installation of the annealing furnace are carried out from the perspective of process and production, ensuring that the equipment is sophisticated and reliable, achieving all the functions of the annealing furnace.

1.2 Insulation and sealing: Multi-layer composite insulation materials and strict filling processes are used to ensure excellent insulation and sealing performance of the annealing furnace shell.

1.3 Control: According to process requirements, the electric heating devices are reasonably configured, high-quality automatic high-temperature butterfly valves are selected, and a reasonable wind system design is implemented to ensure that the glass is slowly cooled down in the important annealing zone, and the annealing furnace is fully automatically controlled.

1.4 RUIXIN's modular form facilitates rapid installation.

1.5 The use of electric heating is simple to operate, pollution-free, and almost requires zero maintenance.

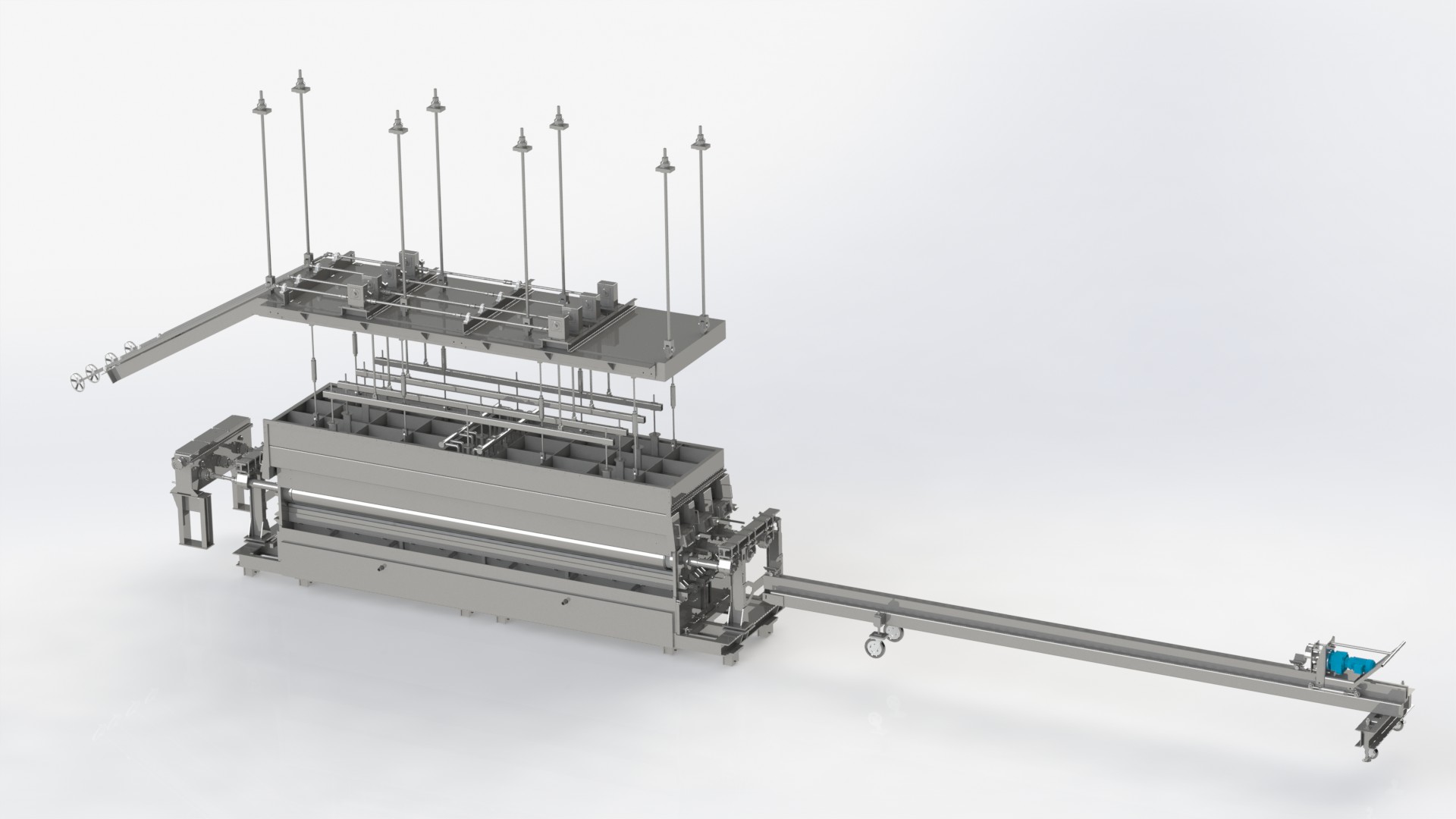

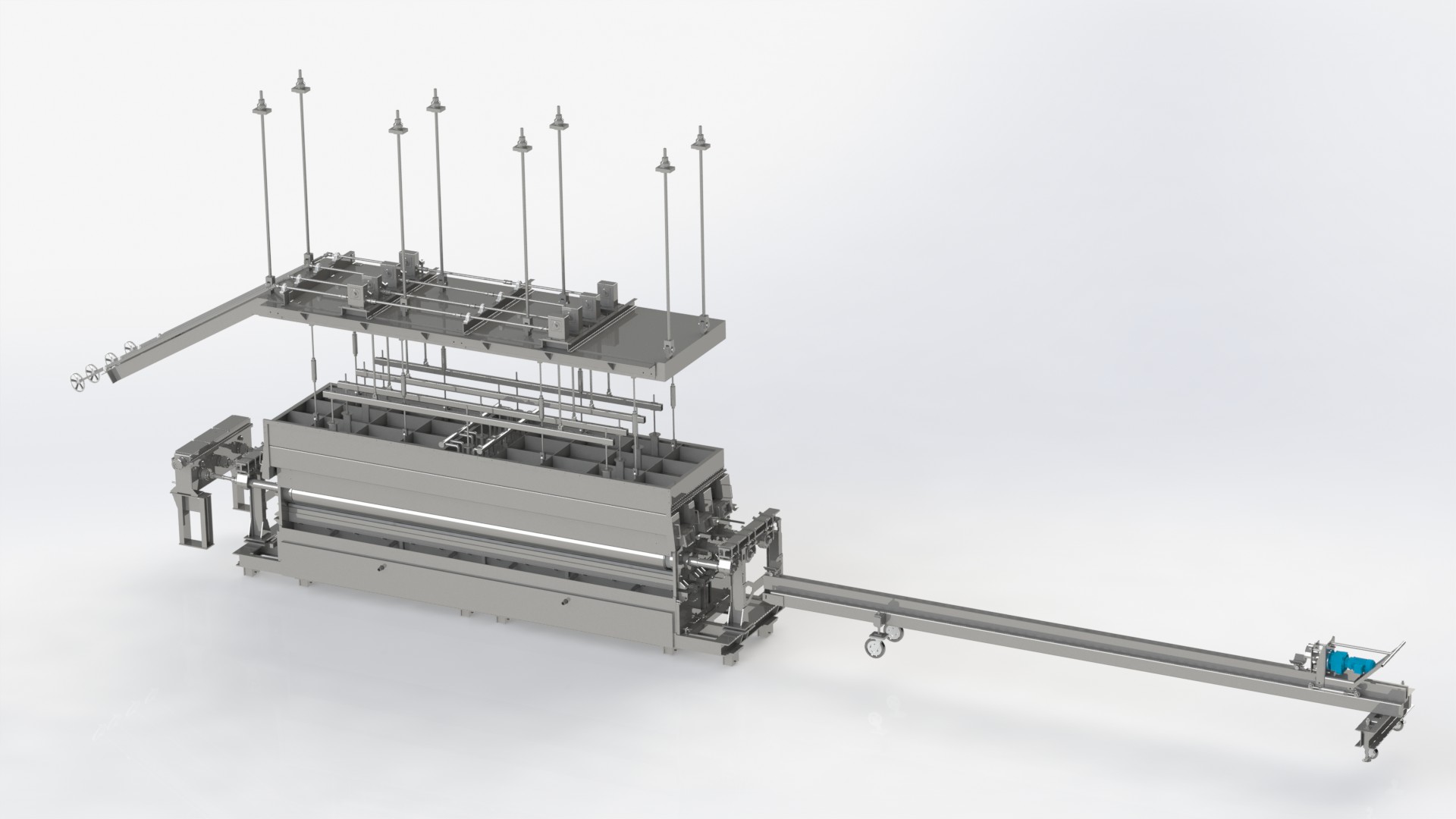

2. New Type of Dross Box for Float Glass Production Line The RUIXIN new type of transition roller table has been successfully developed by summarizing the existing problems in domestic-made transition roller tables, absorbing the essence of foreign proprietary technologies, and combining the experience of domestic float glass production practices. Its main features are as follows:

2.1. In response to the poor performance of the tin wiping device on domestic transition roller tables, we started from structural design, improved the structure, selected special materials, and implemented corresponding control measures in manufacturing and installation. The sealed pneumatic lifting method is adopted to achieve dual functions of tin wiping and sealing.

2.2. A roller changing trolley is set up, which facilitates the convenient replacement of rollers.

2.3. The sealing of the dross box cleaning hole ensures no air leakage, making the transition roller table a space fully filled with high-purity N2 gas.

2.4. SO2 inlets are reserved, and SO2 is introduced at an even flow rate and an optimal distance from the glass slab, overcoming defects such as cracks, burns, and fogging that are prone to appear on the glass slab.

2.5. The structure of the metal curtain has been improved, achieving the best sealing effect and flexible lifting of the outlet curtain, ensuring stable slot pressure, and reducing tin seepage and adhesion.

3. On-line Cleaning Equipment for Float Glass Production Line

4. Automatic Control System for the Tweels on the Float Glass Production Line